Depending on your professional needs for incorporating prototypes and manufacturing, you will probably have to choose between CNC machining and 3D printing. Although both are modern-day manufacturing techniques, there are also significant differences in multiple features, which will eventually determine the technology you need to incorporate to create your products.

Comparing 3D Printing To CNC Machining Services

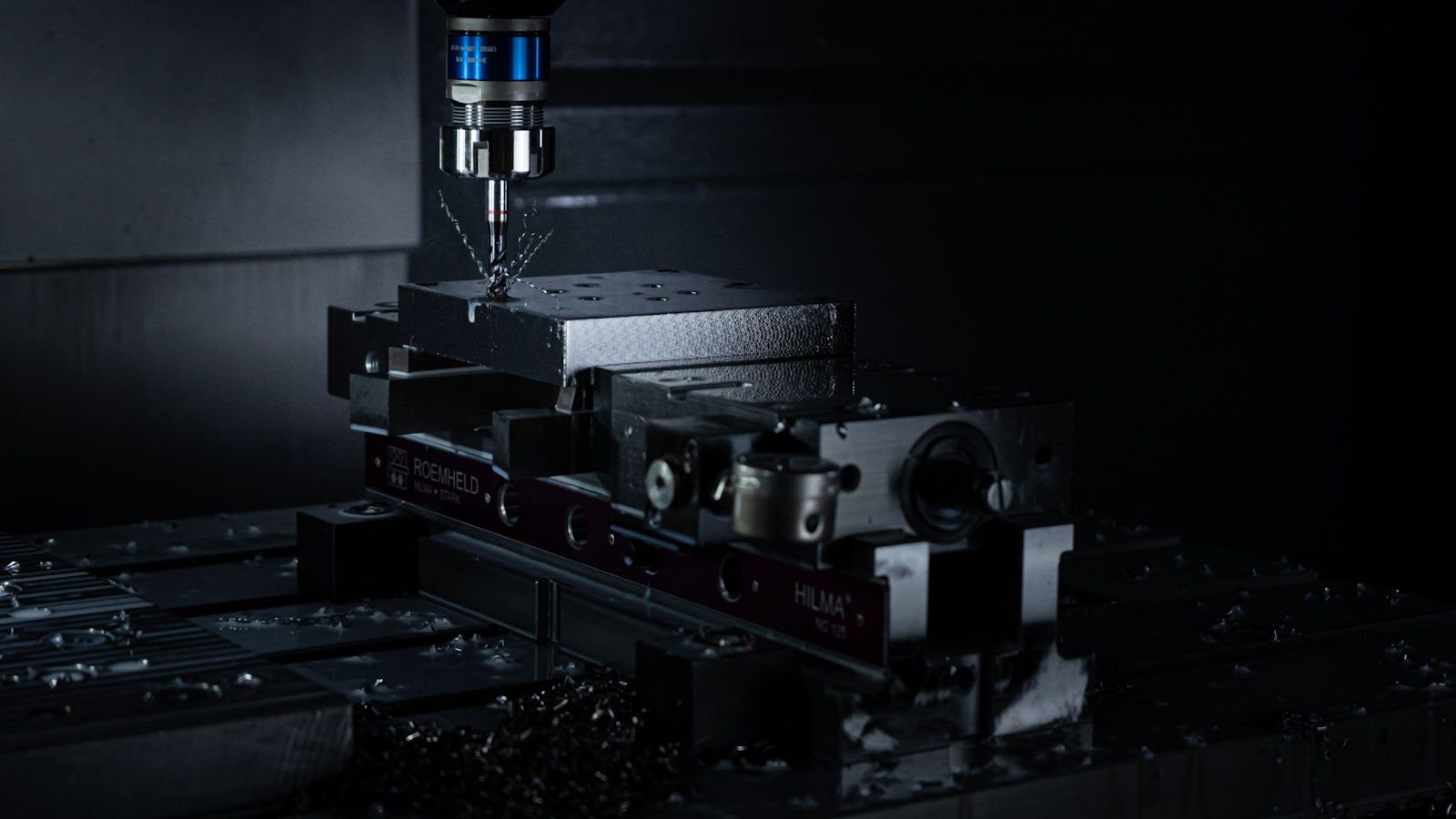

CNC machining is what is referred to as a subtractive manufacturing technology. In contrast to 3D printing, the manufacturer usually starts by obtaining a composite chunk of material and then taking out material to conclude the form of the desired part. This machine constitutes an assortment of sharp rotating tools and cutters.

By far one of the most widely used approaches to producing both one-time applications and high volume outputs, CNC machining provides superb repeatability, is highly accurate, and offers a broad spectrum of materials and exterior finishes. On the other hand, 3D printing, also known as additive manufacturing, produces assembly parts via adding layer-by-layer material and necessitates no particular tools, keeping the primary setup costs at a low level.

Below, we’ll showcase the most significant features of both and compare 3D Printing To CNC manufacturing processes so that you can decide on your own which one you need to elevate your business.

CNC Machining

Being thought of as the more traditional approach to manufacturing parts, CNC manufactures parts with subtractive manufacturing. Among the list of advantages, we can include the outstanding dimensional accuracy and many materials compatible with the machine, such as wood, metals, and plastics. Machines like CNC milling and lathe will also save a lot of time.

Moreover, since CNC machining starts from a single piece of material, individual parts are structurally more rigid than 3D-printed parts. Therefore, 3D-printed parts are more prone to cracking through every build layer in that context.

When the design process ends, parts are ready to be produced, and CNC comes into play. Besides the variety of materials, advantages include each functional component’s durability and temperature permissiveness and the minimal variation you can manufacture them, being as little as 0.005” or 0.0127 mm.

The downsides come in the form of required pre-production checks, the initial setup, and the time for computer-aided manufacturing (CAM). In addition, making prototypes with CNC machining can be really costly, as it derives its value from a phase in production when more significant quantities are required.

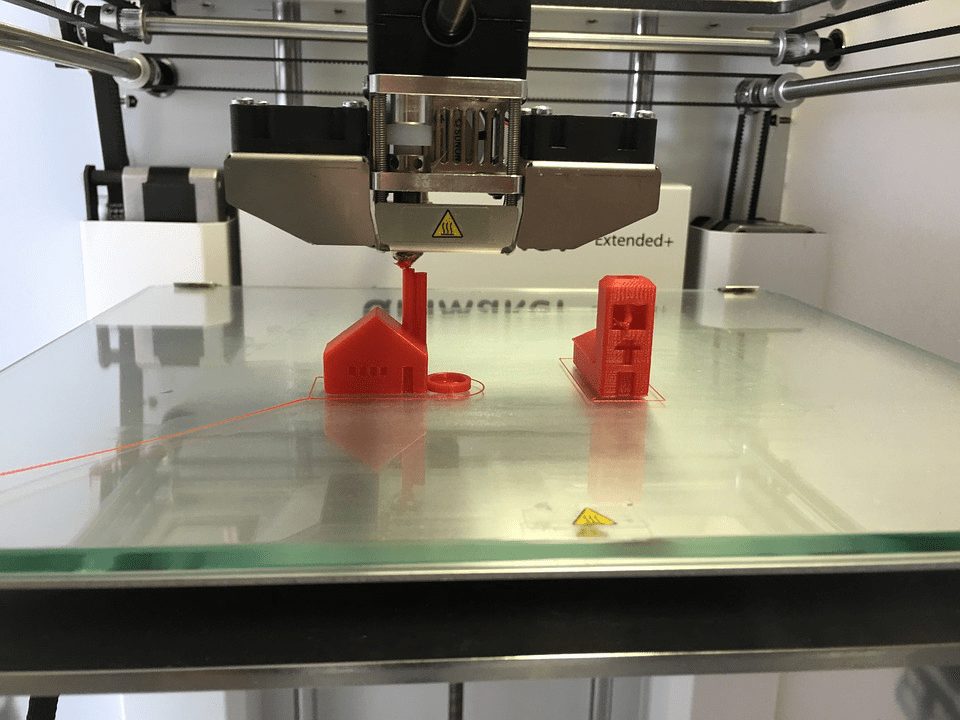

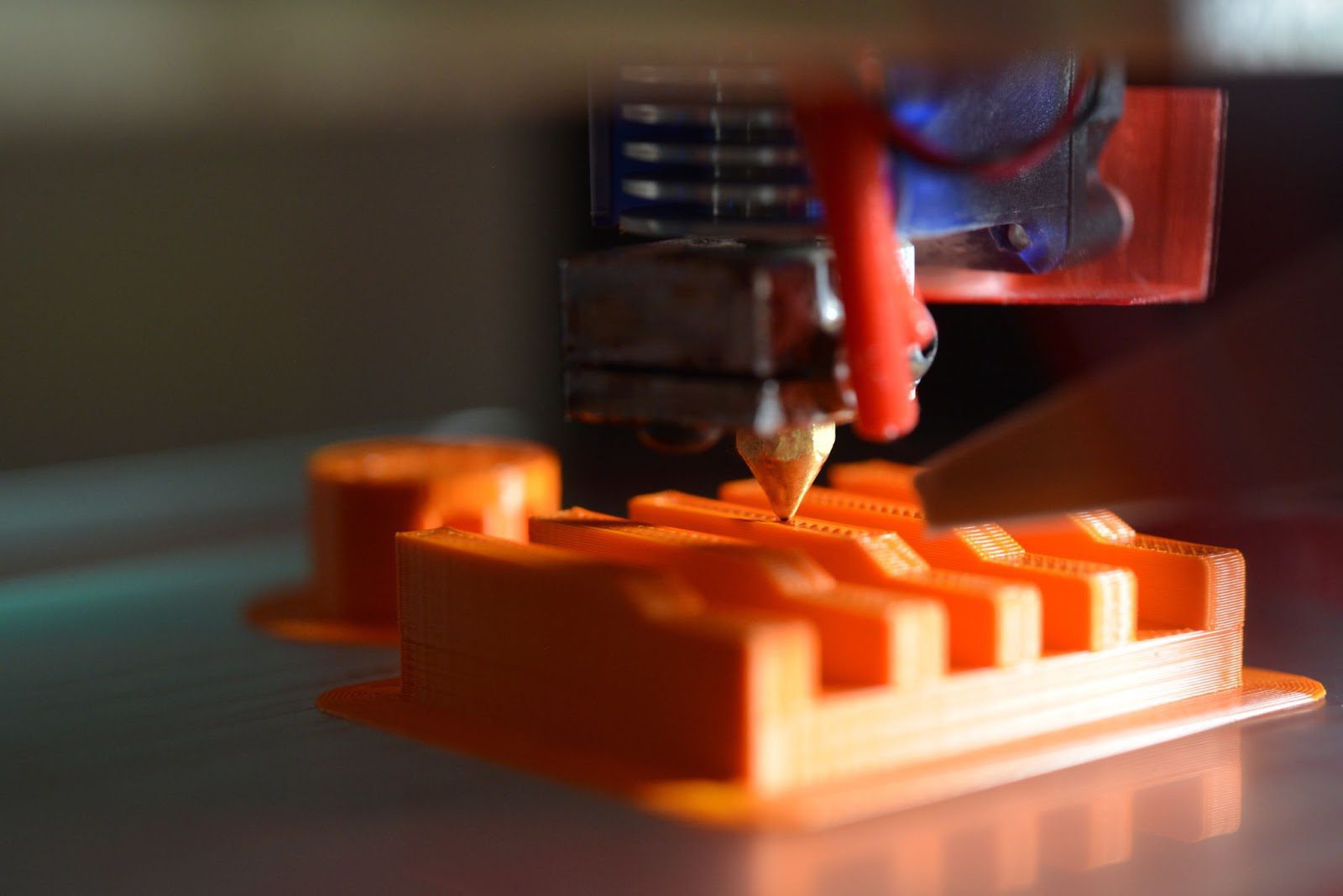

3D Printing

3D printing goes about producing parts by layering them bit by bit. Materials used include plastic and metal powders, plastic filaments, and resins. These need a source of energy to be fused, which can come in the form of a laser or what is called a heated extruder. This energy hardens the materials to deliver the part into finalization.

The pros of additive manufacturing represent the shaping freedom, the cross-sector applicability, the precision, and the savings seen in weight by reducing waste, making this technology superior in cultivating materials costs. Another crucial advantage of 3D printing is the possibility of manufacturing very complex geometries. Furthermore, the easy forming of plastic makes an organic design quickly produced with powder bed fusion processes.

The most time-consuming part of the whole process is the clean-up and the after-production of the manufactured parts. However, many geometry limitations apply when additive manufacturing is considered compared to CNC machining. Also, supporting structures need to be implemented in almost all cases, which get detached after processing.

Deciding Which Process To Use

Luckily, we provide some guiding principles you can utilize so your choice best suits the needs of your proprietary setting. Generally speaking, each piece that needs to be produced with minimal struggle would be CNC machined. You cannot compete with CNC when we talk about high-quantity manufacturing.

On the other hand, 3D printing should be applied in the instances when: very complicated topologically optimized geometry is needed, and conventional methods fail to rise to the task of producing such parts; when the delivery time for completing the whole process is crucial, as 3D printing can achieve this in a day; if you need to cut costs and produce only several pieces-3D printing is usually less costly than CNC.

The Bottom Line

The bottom line is that CNC machining provides higher dimensional precision, and the characteristics obtained for the parts tend to reach greater mechanical endurance. Only if the output is in the lower numbers does 3D printing supply you with lesser costs.

Therefore, additive manufacturing was not invented as a replacement for CNC, on the contrary, it is supposed to complement only a limited number of solutions, which cannot be applied throughout the marketplace. CNC operates flawlessly and gives you a higher quality in most circumstances.