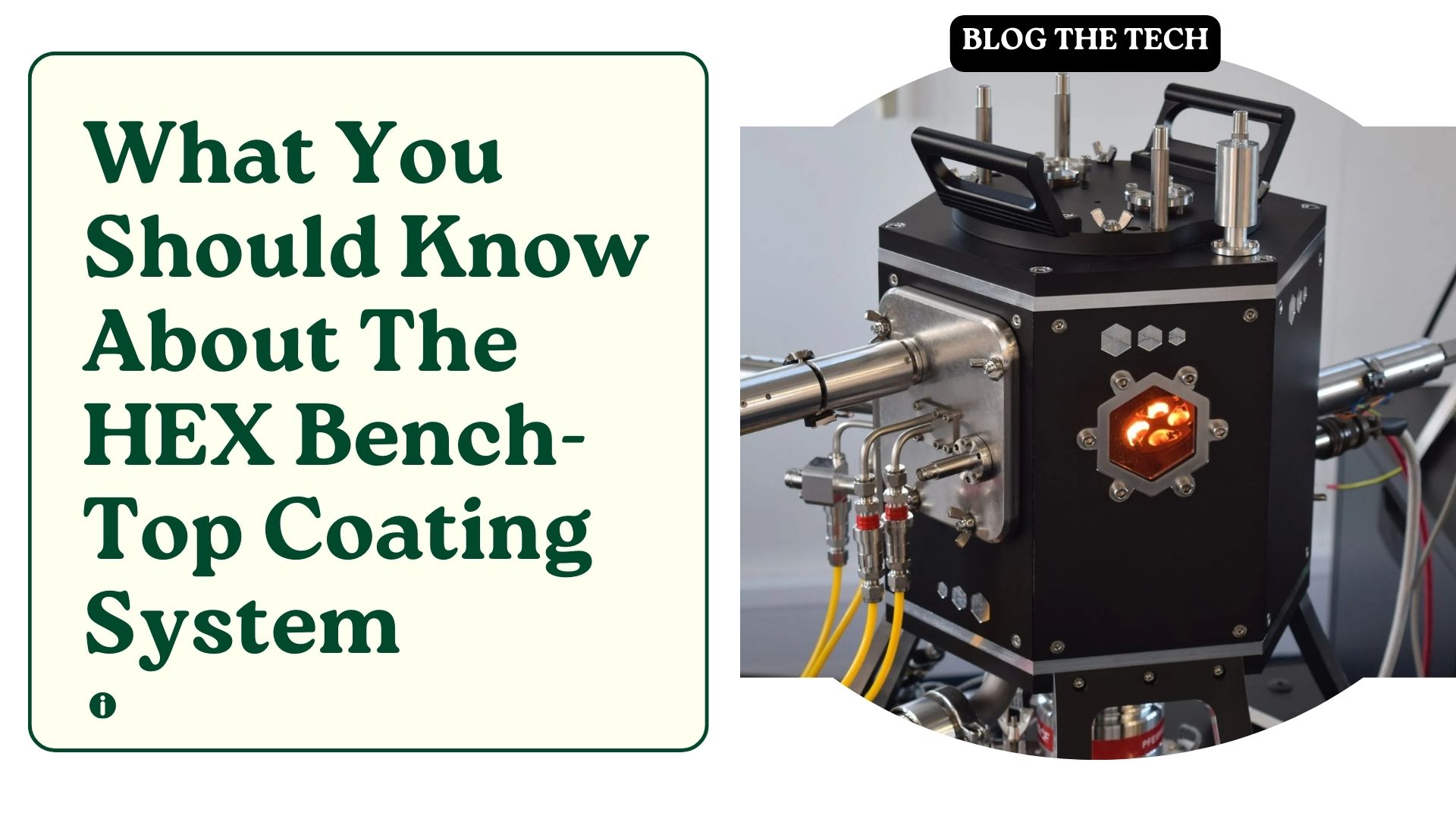

The HEX coating system streamlines the process of applying thin-film coatings to substrate materials. Using electricity and heat, this physical vapor deposition (PVD) technique paints the surface of a particular substance with a durable, anti-corrosive layer.

Thin film deposition devices from the HEX series give you a wide variety of options for use in research and outdoor applications. The unit can be expanded from its starting point of a base system to include a wide variety of source instrument configurations. These enhancements are modular and easy to implement, providing an economical option with minimal impact on system uptime.

Designed for research and development applications across various industries, such as electronics, optics, and biomedical, the HEX Bench-Top Coating System delivers consistent, high-quality performance. No matter where your research leads, the HEX system provides the support and functionality required for thin-film deposition processes.

This blog will further explore the key features and benefits of the HEX Bench-Top Coating System, examine the wide range of applications it supports, and discuss how this cutting-edge technology can transform your thin film deposition processes.

Features and Benefits of The Hex Series

The advantages and benefits of the HEX Bench-Top Coating System make it a fantastic choice for researchers and developers. Here are some of the system’s primary features and benefits:

- Compact and user-friendly design

- High-Precision Coating

- wide range of deposition techniques

- customizable and flexible configuration

- Automated Operation and Data Logging

- Versatile Applications

Compact and User-Friendly Design

The compact and user-friendly design of the HEX Bench-Top Coating System makes it simple to operate and maintain. The system includes an easy-to-use user interface, streamlining the setup and operation procedures. It also provides safety measures like interlocks and pressure sensors to ensure safe and efficient functioning.

High-Precision Coating

The method enables researchers and developers to achieve homogeneous and regulated coatings using high-precision coatings. The system employs a variety of deposition processes that will allow exact control over coating thickness, homogeneity, and composition. It also provides real-time monitoring and control of the deposition process, allowing users to adjust the process parameters to achieve the desired coating qualities.

Wide Range of Deposition Techniques

The HEX Bench-Top Coating System includes a variety of deposition processes, such as thermal evaporation, sputtering, and electron beam evaporation, that can be used to coat metals, ceramics, and polymers. The technology also allows users to swap between multiple deposition procedures and target materials, allowing them to experiment with different coating options.

Customizable and Flexible Configuration

The system has a configurable and adaptive design, allowing users to customize it to their research needs. It can be outfitted with various deposition sources, substrates, and accessories like masks, shutters, and collimators. Additional features and capabilities, such as in-situ monitoring and substrate heating, can be incorporated into the system for improved performance and personalization.

Automated Operation and Data Logging

Users can program and automate the deposition process using the system’s automated operations and data-logging functions. Furthermore, it can save and track deposition process data such as deposition rates, temperatures, and pressures, which can be used for future analysis and development.

Versatile Applications

The HEX Bench-Top Coating System is suitable for various electronics, optics, and biomedical applications. The system can coat various parts and substrates, including sensors, MEMS devices, and optical components, making it a versatile solution for various industries.

What Coatings Can the HEX System Support?

The HEX Bench-Top Coating System is a versatile platform that may be used for various coating processes, such as thermal evaporation, sputtering, and electron beam evaporation.

Thermal evaporation involves:

- Heating a material to its boiling point within a vacuum chamber

- Allowing the material to evaporate and subsequently condense on a substrate.

- Creating a thin film coating as a result.

This process is ideal for coating metals such as aluminum, gold, and silver and is extensively employed in the electronics and optics industries.

Sputtering is another coating method that involves bombarding a target material with high-energy ions, causing atoms or molecules to be ejected and then deposited onto a substrate, forming a coating. This versatile process is commonly used to coat various materials, including metals, ceramics, and polymers.

Electron beam evaporation is a high-vacuum deposition technique in which an electron beam evaporates a material, which condenses onto a substrate to form a thin film coating. This method is often used to deposit metal and oxide coatings and is suited for high-precision applications requiring perfect control over coating characteristics.

Overall, the HEX Bench-Top Coating System covers diverse coating processes and materials, making it a versatile and indispensable tool for researchers and developers in various industries.

Deposition Sources to Customize Your HEX Process

Depending on your required applications, deposition sources to customize the HEX are available to ensure the best fit for your needs. If you need help determining which source is right for you, please consult a technical specialist.

TAU E-Beam Evaporator (Metals)

The top-notch (sub-monolayer) mini E-beam evaporators are ideal for ultra-thin metal film deposition with dependable process control. The lineup includes single-pocket and four-pocket sources, and the control electronics enable up to four sources or pockets to operate concurrently. Materials can be evaporated from rods or contained in a crucible.

TES Thermal Boat Source

The TES thermal boat source allows for the integration of various thermal boats to deposit both metals and organic/polymer materials. This cost-effective option delivers adaptability and efficiency in the deposition process.

FISSION Magnetron Sputtering Source

Tailored for 2″ diameter targets, these sputter sources feature SmCo magnets and accommodate target thicknesses from 0.5 to 6mm for non-magnetic materials and up to 1mm for magnetic materials. The sources work seamlessly with DC, RF, pulsed DC, or HIPIMS power supplies, offering a versatile experience.

ORCA Organic Material Deposition Source

With a temperature range of 50 to 600°C, the ORCA organic deposition source facilitates the precise evaporation of delicate organic materials. The process is made possible through water cooling and a temperature feedback loop, ensuring the highest level of control during the procedure.

Conclusion

The HEX Bench-Top Coating System is a game-changer for researchers and professionals who need a reliable, versatile, and user-friendly solution for their thin film deposition endeavors. It’s an invaluable addition to any laboratory or research facility with various customizable deposition sources and supported coating materials and processes.

Moreover, the system’s intuitive interface, automated operation, and data logging capabilities ensure that users of all experience levels can effectively conduct thin film deposition experiments. By offering a customizable, high-performance, and cost-effective solution, the HEX Bench-Top Coating System is revolutionizing the thin film deposition landscape, empowering researchers to push the boundaries of their studies and develop groundbreaking materials and applications.